So, this is where things start to get smarter!

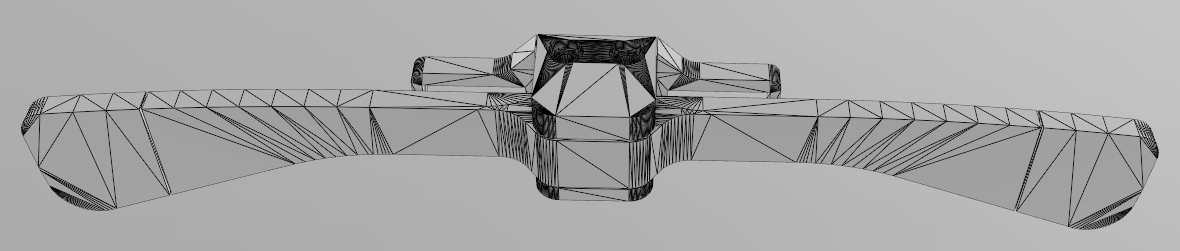

It’s made of 4 pieces, the main shifter arm, the base and two pieces that hold the arm in place.

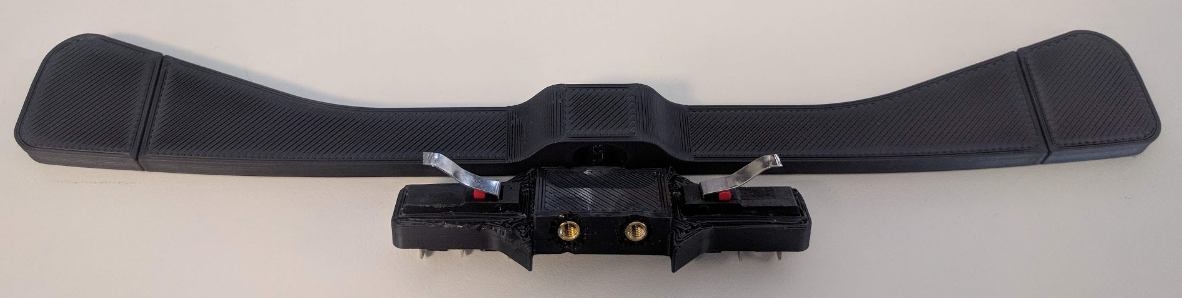

The main base requires M3 inserts, I had initially tried to glue these in with a bit of Gorilla Glue Gel, however I was printing most of this in PETG rather than PLA, so imagine trying to glue 2 water bottles together (hint, not fun).

I needed another idea for this, and luckily a friend of mine, suggested putting the inserts on a soldering iron then dropping into place so that they would melt in bonding to the plastic… and that made things so much nicer, easier and cleaner. Thanks for the tip!

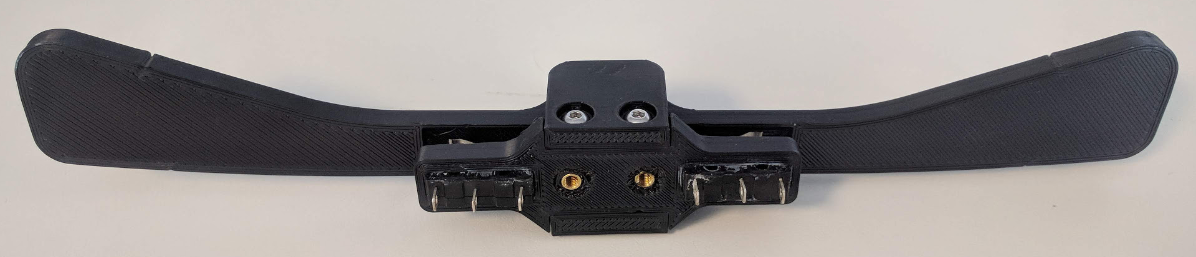

You can see the brass inserts in the image above, that is the main body to the shifter. Within the body are 2 microswitches, within the shifter arm you can see the gap where the two clips will go to, it’s best to have a bearing in here so that it gives the fluid motion. Cool thing from this, it allows up and down shifts from the same paddle (like the real wheel does).

Here are the switches bent out a bit, so that they click nicely on even input from either side.

Good model and well thought out, it allows up and down shifts from either paddle, using the microswitches which give a nice spring back and click to confirm input.