So, the clutch is a lot more fiddlier than I thought, even after getting the springs in place.

My first issue, was having the Arduino become a joystick so that I could utilise them, as my LeoBodnar board would only allow on/off… I couldn’t find anything that would work with either the UNO or Nano – everything I found and tried just wouldn’t work properly or at all.

Again, with more help from SimHub but this time from Melly I over came the first issue, which was having the wrong type of Arduino! So, I needed either Leonardo or Pro Micro which is important as it turns out that they have USB HID Descriptors, which means we can use it as a joystick/keyboard etc.

The second part, again from Melly, was the sketch itself. I had seen a few tutorials online on how to put the joystick sketch and utilise PIN for buttons, but before my Leonardo and Pro Micro turned up, he had created the sketch! Already taking into consideration of a bitepoint finder. So as you probably know, most F1 teams run two clutch paddles, with the aim that they start moving once releasing one paddle and then slowly release the other one as they gain more speed.

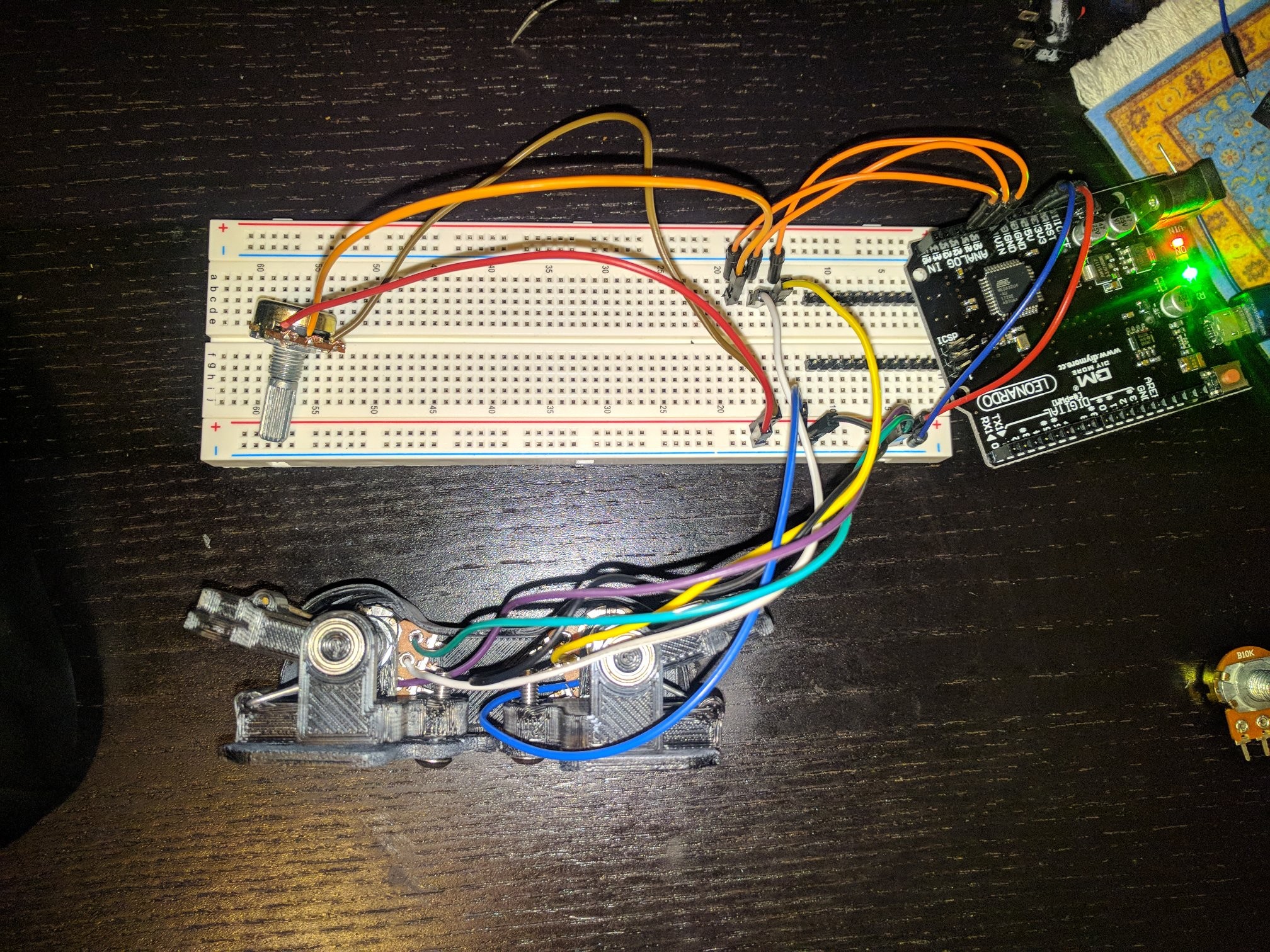

So the bitepoint in games are different across games (and cars?), how are you going to adjust this for each scenario? Make it adjustable! So by adding an extra 10k pot into the equation, and the smart sketch, it now factors this in as a variable as it can change. So as DC explained above, I loaded AC, I sat on the start of Mugello held the clutch in and put my foot down, adjusted the bite point until I was moving. So on the start, I hold both in, when the lights go out I let go of my left clutch and the car begins to move, and I slowly release the right clutch as accelerating forward.

As you can see, it’s not close to being final but you can see the 3rd 10k pot which is the adjuster.

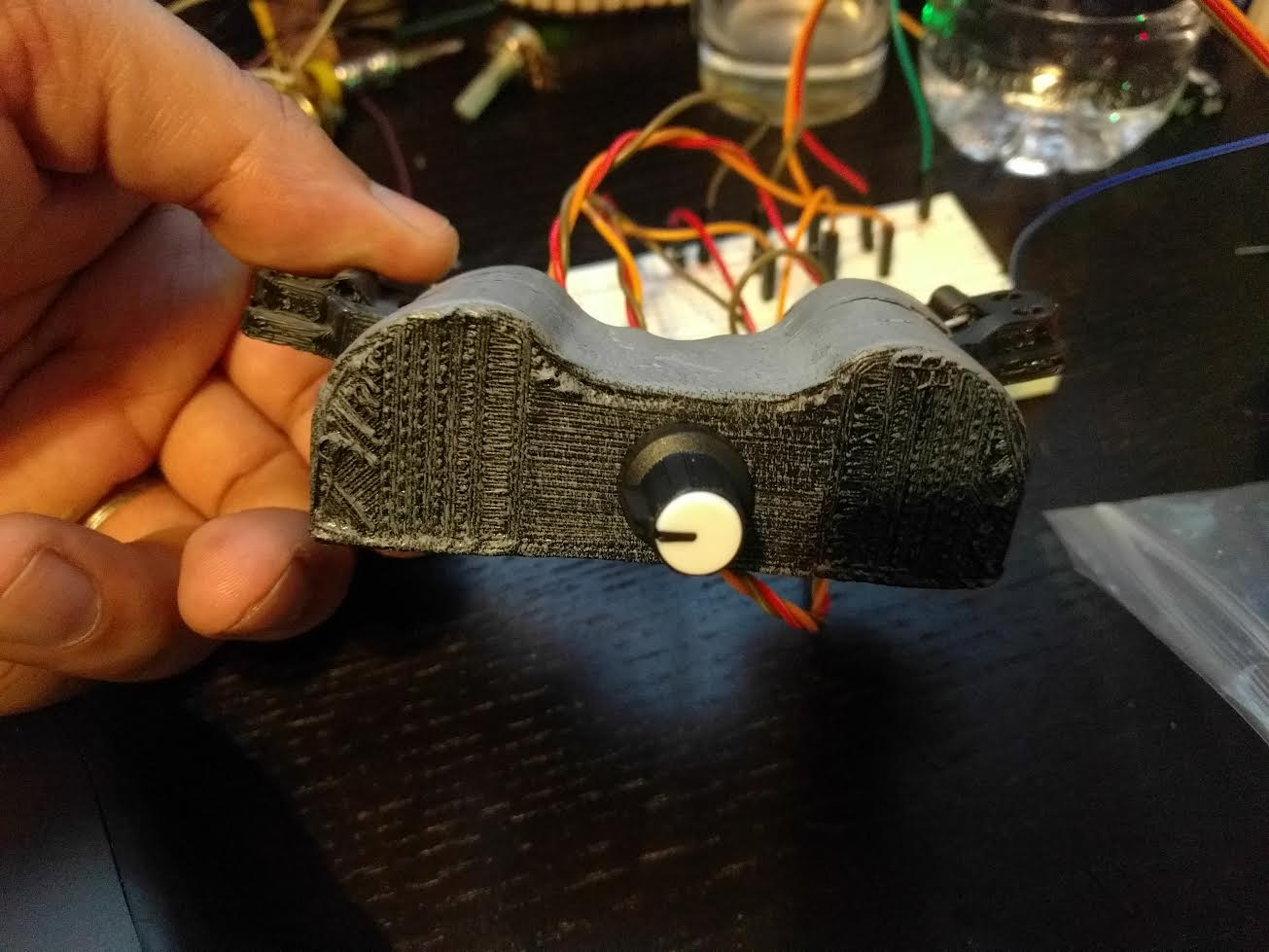

Ignore the plastic quality for this – it’s not the final print/finish. You can see that I’ve just burnt a whole through the bottom of the casing to fit the bitepoint adjuster.

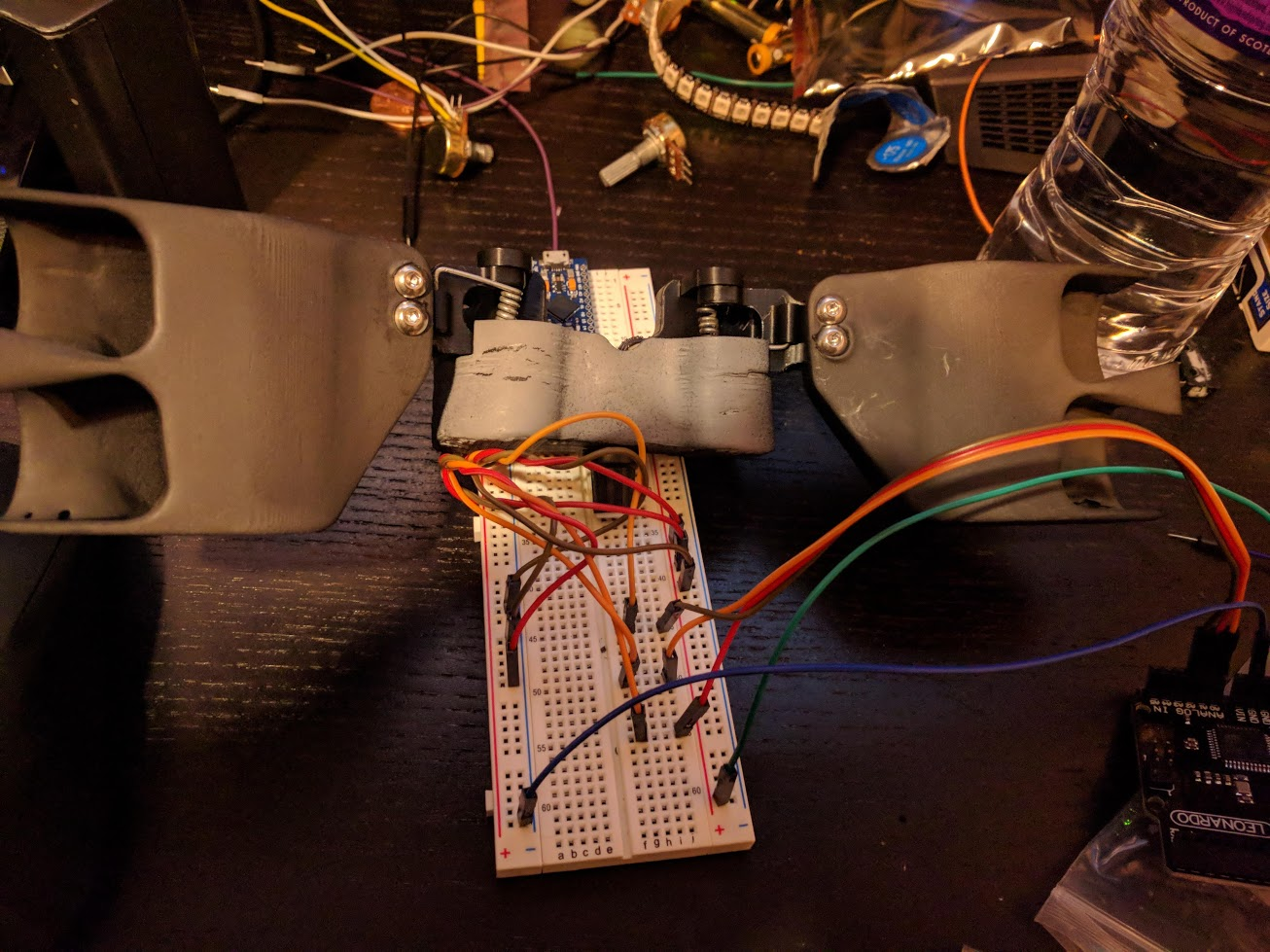

So, as you can see it ‘together’ – it felt really nice for something that wasn’t even close to being final. This is where I ran into issues though… after adjusting sensitivity of the movement, as the pot aren’t really moving a lot when the paddle is pressed, I started to get random readings… so instead of being 0 for both of them, they were occasionally being stuck on 20-30 and values going up when pressed. I have a feeling that it’s most likely the pot bar not turning with the spring/plastic piece properly on the way back, I thought it was slippage of the pot itself but there’s not much room for it to move and it’s bolted in to prevent that. Most likely I will have to blob a bit of hot glue to the pot and stick it inside the casing so prevent any movement, and then glue the bar to the moving part so confirm it doesn’t slip.

Here is a download to the current sketch, I will update going forward as things change.