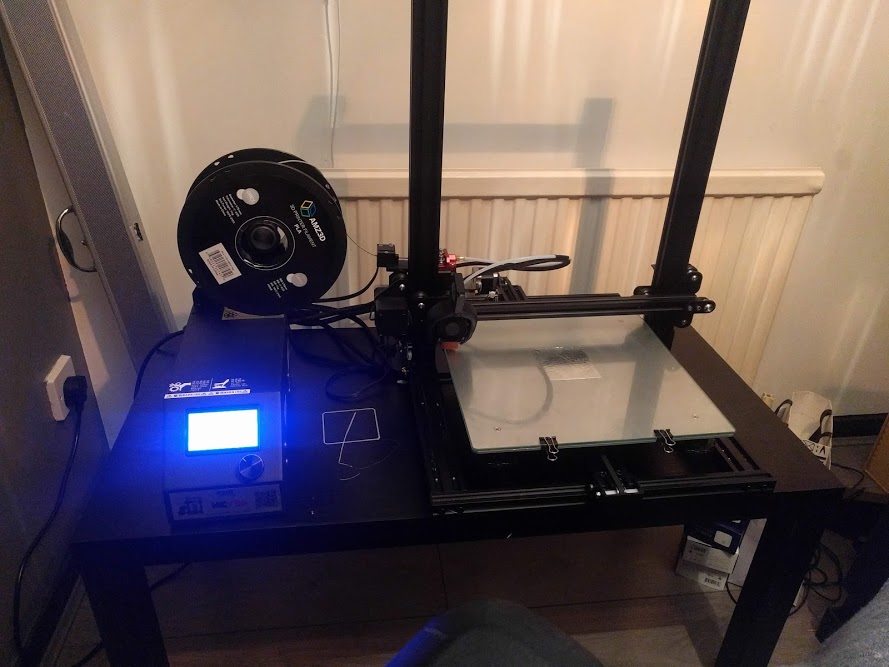

I have a Creality CR-10s (hictop), I’ve made a few modifications to it however found myself going back to the stock setup as I found with the fang (high clearance, not petsfang) kept getting knocked (by me!) and eventually broke.

Whilst it gave a good view to the print, it didn’t really change much in quality and as mentioned before, went back to stock but with a Noctua fan.

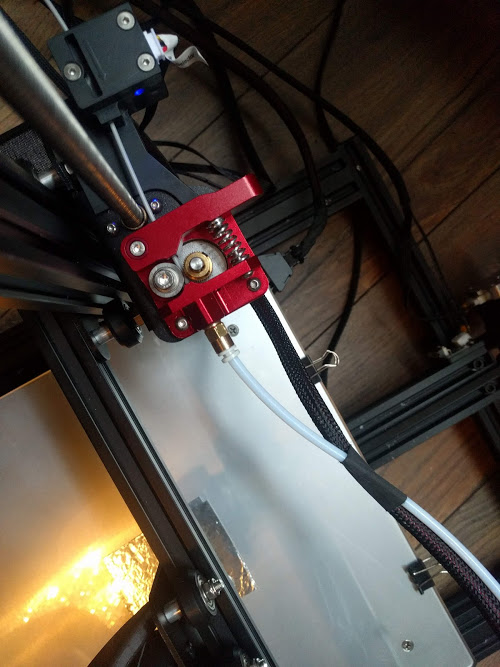

Another change was the metal extruder drive feed, this made quite a big difference for me, as I was having issues with the filament not being pushed through properly, sometimes it would grind as if it’s not pushing anything through, and then occasionally it would click as if it was unable to extrude it.

Along with the damper install, the printer runs pretty smooth – I’ve not had many issues with it, out of the box it’s worked pretty well.

I then looked into upgrading the Marlin software, and went with the TH3D variant as my aim is to get the ezabl installed, one day. This also enabled thermal protection so the printer didn’t burn the house down, which was a bonus. It also had manual mesh levelling which would see me through to getting the auto bed level kit.

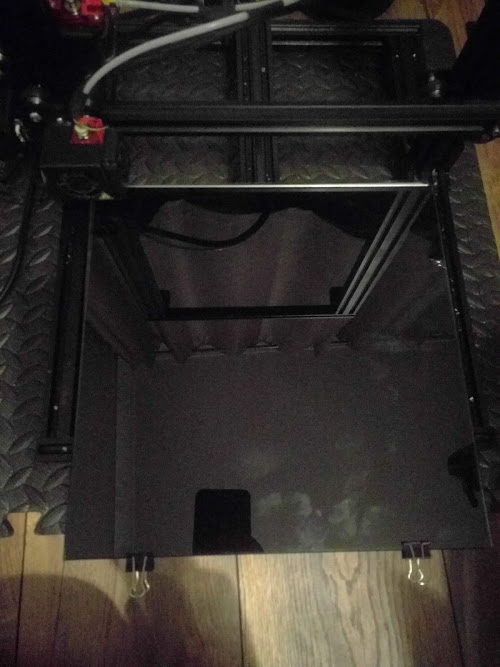

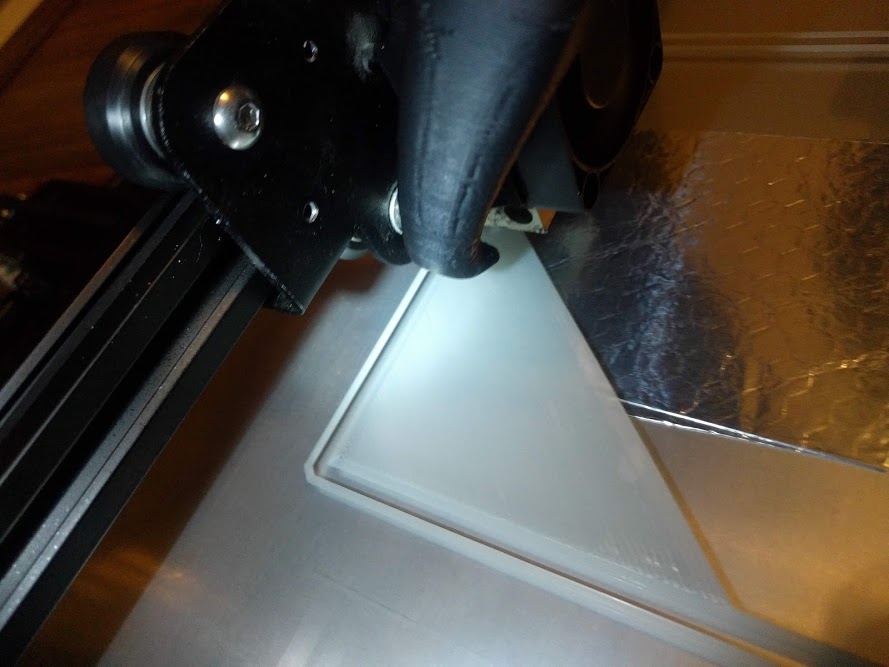

If you’re wondering why there is a piece of foil under the stock glass – it’s because the stock glass isn’t very flat 🙂

I since went to a local glass store (thanks to my neighbour for the suggestion), and had a few bits made to measure (CR10 glass is 310x310mm), as I didn’t bother with the fugly inserts, I went for black glass (not thinking about when I print black PLA/PETG…) And have setup manual mesh level, so we’re all good to go.